FTO (Fluorine-doped Tin Oxide) glass and ITO (Indium Tin Oxide) glass are both types of conductive glass, but they differ in terms of processes, applications, and properties.

Definition and Composition:

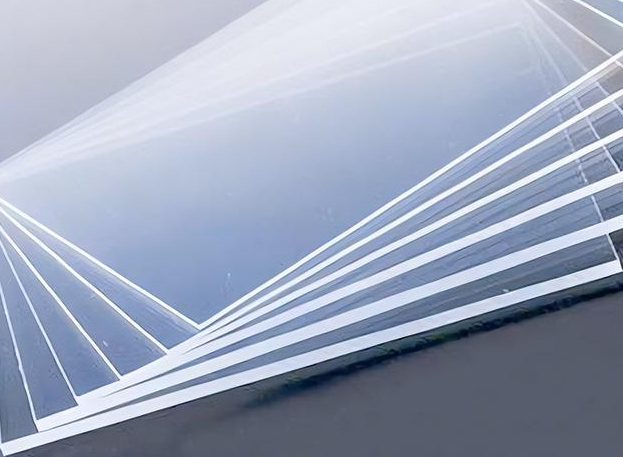

ITO Conductive Glass is glass that has a thin layer of indium tin oxide film deposited on a soda-lime or silicon-boron-based substrate glass using a method like magnetron sputtering.

FTO Conductive Glass refers to tin dioxide conductive glass doped with fluorine.

Conductive Properties:

ITO Glass exhibits superior conductivity compared to FTO glass. This enhanced conductivity results from the introduction of indium ions into tin oxide.

FTO Glass, without special treatment, has a higher layer-by-layer surface potential barrier and is less efficient in electron transmission. This means that FTO glass has relatively poorer conductivity.

Manufacturing Cost:

The manufacturing cost of FTO glass is relatively lower, about one-third of the cost of ITO conductive glass. This makes FTO glass more competitive in certain fields.

Etching Ease:

The etching process for FTO glass is easier compared to ITO glass. This means that FTO glass has relatively higher processing efficiency.

High-Temperature Resistance:

FTO glass exhibits better resistance to high temperatures than ITO and can withstand temperatures up to 700 degrees. This implies that FTO glass offers greater stability in high-temperature environments.

Sheet Resistance and Transmittance:

After sintering, FTO glass shows minimal changes in sheet resistance and offers better sintering results for printing electrodes compared to ITO glass. This suggests that FTO glass has better consistency during manufacturing.

FTO glass has higher sheet resistance and lower transmittance. This means that FTO glass has relatively lower light transmittance.

Application Scope:

ITO conductive glass is widely used to manufacture transparent conductive films, shielded glass, and similar products. It offers appropriate shielding effectiveness and better light transmittance compared to conventional grid material shielded glass. This indicates that ITO conductive glass has a broader range of applications in certain areas.

FTO conductive glass can also be used to produce transparent conductive films, but its application scope is narrower. This might be due to its relatively poorer conductivity and transmittance.

In summary, ITO conductive glass surpasses FTO conductive glass in terms of conductivity, high-temperature resistance, and application scope. However, FTO conductive glass holds advantages in manufacturing cost and ease of etching. The choice between these glasses depends on specific application requirements and cost considerations.